Technologies

Fully integrated vertical process

F.O.M.T.’s main competitive leading edge has always been its ability to deliver parts ready for use on the customer’s assembly lines. The process stretches from design (simultaneous engineering) adopting the most widely-used specific CAD programs: thus allowing the optimization in the construction of the casting and machining tooling.

The aluminum or zinc alloys castings are then produced using gravity or high pressure die castings technology. Castings are then machined and assembled.

The aluminum or zinc alloys castings are then produced using gravity or high pressure die castings technology. Castings are then machined and assembled.

Engineering

Parts optimization with CAD systems and casting process simulation with FEM analysis. Tooling design with conventional and CAM computerized methods.

Construction of foundry and machining tooling with NC machine tools.

Construction of foundry and machining tooling with NC machine tools.

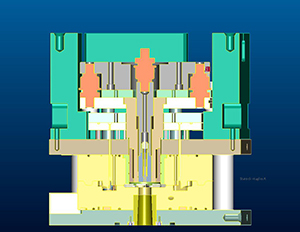

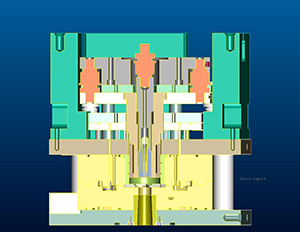

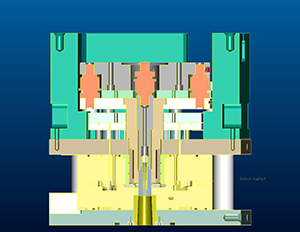

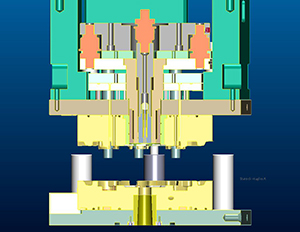

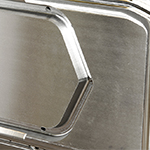

ASC Technology

F.O.M.T. has developed, in collaboration with the “Politecnico di Torino”, an innovative process that is an alternative to the traditional processes of foundry or forging. ASC process (Advanced Squeeze Casting) can be considered as a forging performed on an alloy in the molten state.

The ASC technology can be used to produce parts subjected to relevant static and dynamic mechanical stress, whilst ensuring a significant reduction of production and tooling costs.

The new process is a compromise between expensive processes and it’s able to ensure high mechanical characteristics for the part and not expensive processes with established technological limits.

The ASC technology can be used to produce parts subjected to relevant static and dynamic mechanical stress, whilst ensuring a significant reduction of production and tooling costs.

The new process is a compromise between expensive processes and it’s able to ensure high mechanical characteristics for the part and not expensive processes with established technological limits.

Machining

F.O.M.T. is equipped with two lines of machining centers with CNC machines up to five axes and specific transfer lines.