Quality

Tradition of quality

Quality has always been a top priority for F.O.M.T., as confirmed by the fact that the company set up a Quality Control system way back in 1988, well before this became a major market benchmark. F.O.M.T. is therefore guarantees unswerving quality in all phases of the production cycle in order to obtain a product with zero defects.

A Quality System that operates efficiently day by day as it is known, shared and applied at all levels of the company.

A documentation system that guarantees complete traceability is a further guarantee of product quality.

Inspection methods

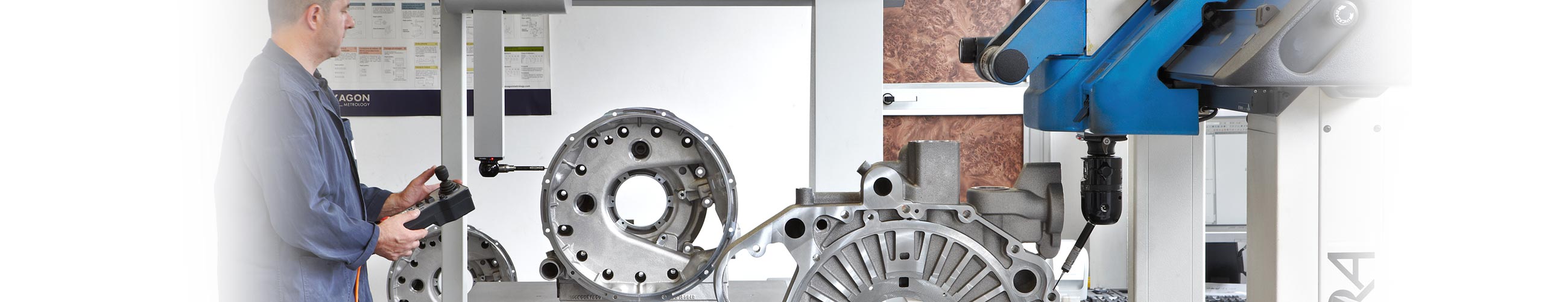

The machining cycle is developed so as to permit to check all the production phases. In the construction phase, tooling is checked using 3D measurement machines and with comparative threshold method systems (CTR).

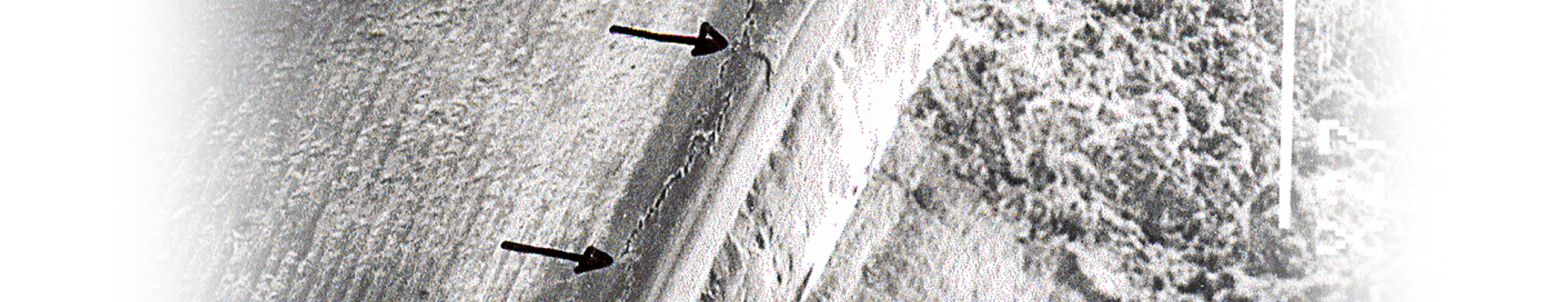

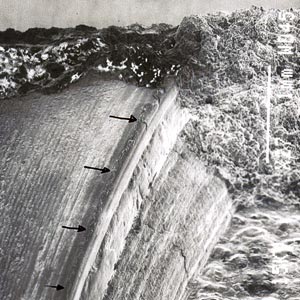

In the foundry, destructive tests are also carried out (quantometric analysis of alloy composition and micrographic structural tests) and radiography and radioscopy tests using two X-ray systems. 3D Coordinate Measurement Machines (CMM) are used for variable-based statistical process control and control gauges for attribute-based statistical process control.

In the foundry, destructive tests are also carried out (quantometric analysis of alloy composition and micrographic structural tests) and radiography and radioscopy tests using two X-ray systems. 3D Coordinate Measurement Machines (CMM) are used for variable-based statistical process control and control gauges for attribute-based statistical process control.

Laboratory

At F.O.M.T., the laboratory activities stretch well beyond conventional process controls, also addressing the study and research phases required by the on-going cooperation with Turin Polytechnic and with the AIM (Associazione Italiana di Metallurgia – Italian Metallurgy Association).

A suite of high precision instruments (micro hardness meter, analytical balance, spectrometer) are used as support in both the research and control phases.

To guarantee constant update and in cooperation with the most highly qualified centers, F.O.M.T. participates in research projects organized by the European Community

A suite of high precision instruments (micro hardness meter, analytical balance, spectrometer) are used as support in both the research and control phases.

To guarantee constant update and in cooperation with the most highly qualified centers, F.O.M.T. participates in research projects organized by the European Community